High standards require the most accurate analysis. That’s where DIA stands apart from other techniques!

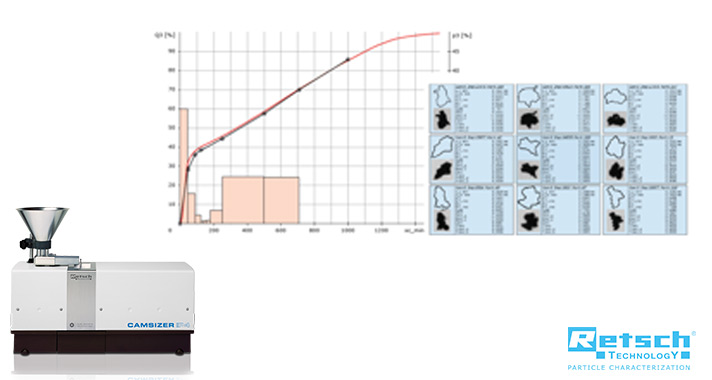

Accurate analysis with Dynamic Image Analysis (DIA)

Higher resolution, better sensitivity, and excellent reproducibility: this is how Dynamic Image Analysis (DIA) improves the characterisation of powders and granulates in both quality control and R&D. This white paper outlines how particle size distribution and particle shape are determined by DIA, illustrated by application examples from the pharmaceutical industry which prove the superiority of the method over sieve analysis and laser diffraction.

Pharmaceutical samples

Traditional techniques for particle size distribution analysis of pharmaceutical samples are sieve analysis, microscopy or laser diffraction. These methods are established in the pharmacopoeia and are used in pharmaceutical laboratories all over the world.

With the introduction of Dynamic Image Analysis (DIA) as an alternative method, it is now possible to measure particle size and shape of powders, granulates, pellets and suspensions of particles > 1 μm. A number of trials clearly demonstrate the advantages of DIA compared to the traditional particle sizing methods.

Many pharmaceutical companies have already recognized the potential of this method and added this technology to their research and quality control labs. Typical application examples are:

- Micronised active ingredients (APIs) and excipients

- Pharmaceutical granulates (e. g. tableting mixtures)

- Size and shape of pellets

- Monitoring of coating processes

- Characterisation of crystalline APIs and excipients