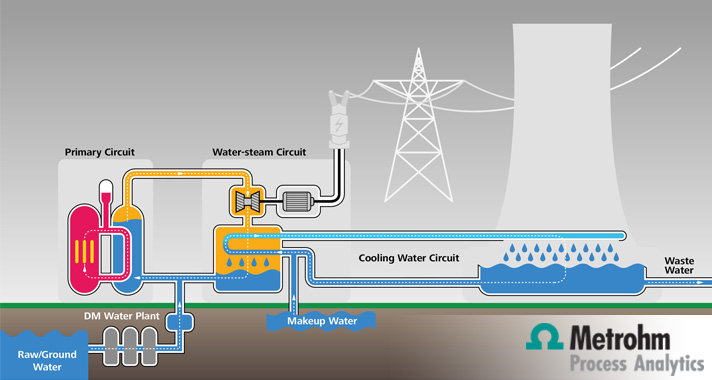

In power plants, corrosion is the primary factor leading to costly and critical downtimes. The water-steam circuits in fossil and nuclear power plants are inherently prone to corrosion, as metal components are constantly in contact with water. Measures to monitor or prevent corrosion are crucial in this context.

Power Plants & Corrosion

Nearly 50% of unplanned downtime in power plants is caused by contaminants or problems in the chemistry of the water-steam circuit, with corrosion being the primary factor.

Corrosion chemistry monitoring helps to minimize loss of efficiency and protect the components coming in contact with steam and water against damage. The mechanisms and associated root causes responsible for most chemistry-related damage and efficiency loss are now very well understood, but the precise conditions at which corrosion and deposition activity begin are still not known. Past and present chemistry guidelines all serve to provide the operator with a warning as to when corrosion and/or deposition activities that place the power generation unit at risk may begin.

Guidelines

Various guidelines define the permissible operating ranges for water chemistry used by power plant operators, including standards provided by the Electric Power Research Institute (EPRI), the European Power Plant Suppliers’ Association (EPPSA), and the International Association for the Properties of Water and Steam (IAPWS). Nuclear power generation is governed by the safety standards of the Nuclear Regulatory Commission (NRC) and the International Atomic Energy Agency (IAEA).

Unique designs

Every cooling circuit has a unique design and thus its own unique challenges. The specifics of the water chemistry to be regulated (and therefore the applicable limits) depend on the type of power plant, the cooling circuit design, and construction materials.

Timely and effective monitoring of power plant water chemistry is critical for maintaining efficiency and safety. By using online analyzers, operators gain the information they need to accurately identify trends and address operational issues before costly problems arise.

Dedicated Online Analysers

Effective cycle chemistry programs depend upon the selection of treatments customized to the specific unit and its characteristics. Treatment control and optimization, in turn, requires rapid, accurate sampling and analytical capabilities. While all power plants can benefit from online analysis of critical parameters such as corrosion indicators and inhibitors for optimum chemistry control, monitoring of diagnostic parameters such as chloride, sodium, sulfate, ammonia, hydrazine, silica and TOC can also be highly advantageous for protection and process optimization. Not only do dedicated online analyzers help to safeguard plant operation and efficiency, but they also provide a continuous record of plant operating conditions for increased plant uptime and to facilitate long-term improvements in productivity.

Metrohm Guide “Dedicated Online Analysers for Power Plants

The new Metrohm Guide “Dedicated Online Analyzers for Power Plants – Monitoring and Protecting against Corrosion” outlines the challenges and the solutions of protecting power plants from corrosions. It presents solutions for analyses of Boric Acid, Uranium, Calcium, Carbon, Silica and Phosphate in the industry. It can be downloaded for free from our website.7