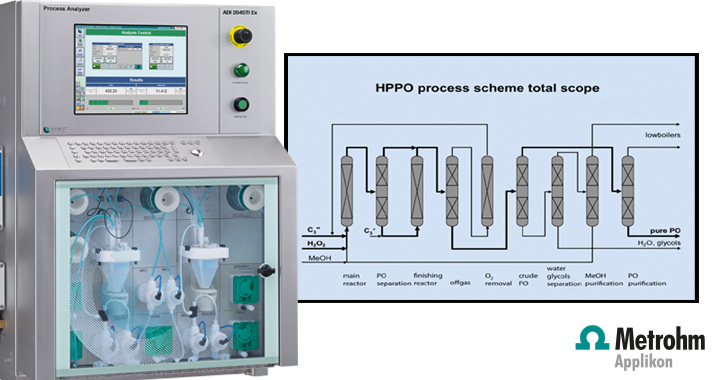

Example of a HPPO plant scheme.

Propylene oxide is an important product for the chemical industries because of its wide range of applications that are predominantly used in the polyurethane and solvent industries. The total PO market is still growing and also the need for a cost efficient and environmental friendly production process. Today’s industry leading technology process “HPPO” (Hydrogen Peroxide to Propylene Oxide) yields PO from propene and hydrogen peroxide using a titanium silicate catalyst.

CH3CH=CH2 + H2O2 → CH3CHCH2O + H2O

Hydrogen Peroxide present in a methanol solvent is used as the sole oxidizing agent and is the critical feedstock and parameter to measure the complete conversion rate to PO. Thus the high demand for accurate and robust on-line process monitoring throughout the whole reaction process. Measuring the H2O2 concentrations in the primary reaction tank plays a vital role to ensure high PO yields while reducing costs with low feedstock consumption. Due to the hazardous environment at the production plant strict safety precautions have to be implemented with all production and process equipment. The ADI 2045TI SS with Purge Control Unit (NEC certified) or ADI 2045TI Ex proof (ATEX) complies to all electrical safety requirements and specifically designed for high throughput processing in a hazardous location.