A reliable and accurate analysis can only be guaranteed by reproducible sample preparation.

The “Art of Milling” describes the process of turning a laboratory sample into a representative part sample with homogeneous analytical fineness. For this task RETSCH offers a comprehensive range of the most modern laboratory mills and crushers for coarse, fine and ultra-fine size reduction of almost any material.

The wide selection of grinding tools and accessories not only ensures contamination-free sample preparation but also adaptation to the specific requirements of such different areas of application as construction materials, metallurgy, foodstuffs, pharmaceuticals or environment.

Particle size reduction of solids or bulk materials is required when the particles are too coarse or the sample is too inhomogeneous for subsequent processes such as analysis, division, mixing or further processing.

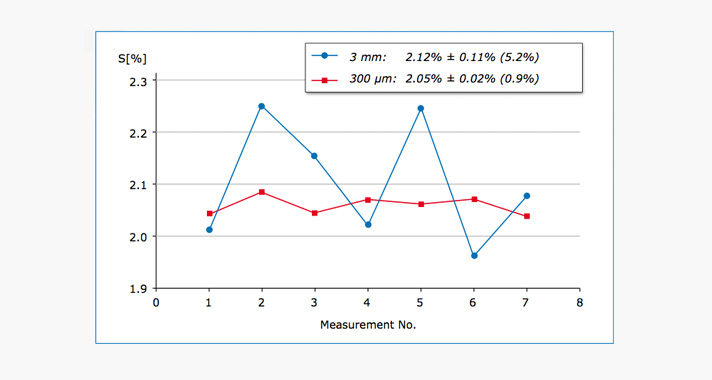

The standard deviation of any subsequent analysis can be minimised drastically by particle size reduction and homogenisation of the analysis sample (see diagram below).

A rubber sample was ground to different particle sizes. The degree of homogenisation increased with decreasing particle size. The subsequent measurement of the sulfur content (measured with an ELTRA CS-580 analyser) showed that the more homogeneous a sample was (red) the lower was the standard deviation, i.e. the more reliable were the analysis results.