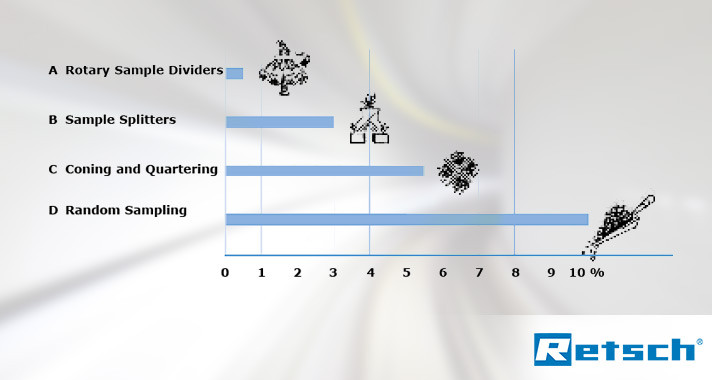

Bulk material, feed size < 5 mm. The diagram shows qualitative variations among part samples for various methods of sampling and sample division.

Large sample volumes

Representative sampling of large sample volumes is an integral part of the physical and chemical analysis of bulk goods and has a decisive influence on the quality of the results. A precisely defined procedure is crucial for this process. The objective of sample division is to obtain representative part samples suitable for the determination of characteristic properties of the original sample.

However, extraction of a sample from the bulk is not always carried out in a way to ensure representativeness. This is a widespread flaw in the quality control process with a negative impact on the subsequent analysis results. Therefore, more attention should be paid to the correct sampling procedure. Sample division is often considered as a labor-intensive process which not always leads to representative results. RETSCH provides some convenient solutions which help to improve working conditions and thereby the quality of the sampling process.

Challenge of sample division

The challenge of sample division is to obtain a part sample which represents the original sample and which can therefore be used directly for analysis. For example, if 200 ml are to be extracted from 60 liters of sample, a sample splitter is often the first choice. A large-sized sample splitter has a feed hopper of 25 l max. and divides the sample into two parts of 12.5 l each in the first step. It is not recommended to split more sample material in one go because the collecting vessels might be difficult to lift due to their weight and the material might overflow.

To obtain 200 ml of representative sample, approximately 20 sample splittings are necessary. It is more than doubtful if these part samples can still be called representative. Not to forget that the use of sample splitters involves dust exposure.