Reducing plant power consumption with FC Bond index testing.

Around half the energy used in most material processing plants is consumed in grinding.

An introduction to the new range of Retsch testing equipment.

Usually power consumption is the single biggest operating cost item and good energy utilisation is critical to project economics. Sizing of grinding mills is mostly carried out by determining the energy required for the duty and selecting an appropriate unit to deliver the energy. This can be done by laboratory testing.

Restch XL includes a range of FC Bond testing equipment for abrasion, crushing working index and a drum mill with interchangeable ball and rod module testing.

Abrasion testing

Abrasion testing with the new AT100 XL. The Bond Abrasion Index quantifies the abrasiveness of an ore. The abrasion index test requires only 5 kg of material, which is crushed and screened to an exacting size range of + 12.7 -19.0 mm. The test uses a small laboratory scale mill with a test paddle that is weighed before and after being rotated in contact with the dry test sample. The difference in weight is designated as the abrasion index, and is used in conjunction with FC Bond formula to predict liner wear and media consumption in rod and ball mills, as well as in crusher lines.

Bond grinding indices

Bond grinding indices

FC Bond testing of grinding indices with the new BT100 XL. The Bond Grinding Indices are useful in predicting the power required for rod and ball mills. They can also be used by operators to assess the power efficiency of an existing circuit.

Ball Module

The ball module is designed to accept a ball charge in accordance with F. C Bond’s standard for Ball Working Index (BWI).

This ball charge is provided with the machine and consists of

- 43 x 1.45” balls

- 67 x 1.17” balls

- 10 x 1” balls,

- 71 X 0.75” balls and

- 94 x 0.61” balls

The optimum number of balls is 285. However as the balls wear their size varies. Accordingly the total number of balls must be adjusted to give a final mass of 20,125 grams. Do not remove all balls of one size and try to maintain the correct proportion of balls by size. Make fine adjustments by adding or removing small balls.

The rod module is designed to accept a rod charge in accordance with F. C Bond’s standard for Rod Working Index (RWI).

This rod charge is provided with the machine and consists of:

- 6 x 1.25 in Dia. x 21in long

- 2 x 1.75 in Dia. x 21in long

Crushing Working Index

Crushing Working Index

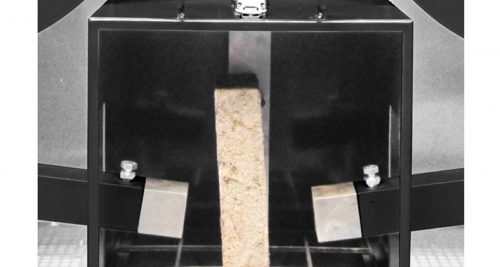

Determining Crushing Working Index (CWI) with the new Retsch IT 100 XL.

The CWI is used to receive the information about the competency of the ore at larger particle size. CWI is used to calculate actual crusher power requirements. This allows to plan the actual crusher power requirements. The test involves twenty pieces of rock or drill core of size + 50 – 76 mm. The pieces are placed in a twin pendulum device and impacted to failure to produce an impact crushing strength, measured in kWh per ton of ore. Twenty specimens are tested to provide a measure of variability of results, as there is a tendency towards heterogeneity in rocks of larger sizes. The standard index is used primarily by crusher manufacturers to assign downrating factors for ore toughness in crusher selection.

Retsch offer an automatic version of the IT 100 XL with a winch motor to raise the hammers, for improved safety and accuracy. A manual version is also available.