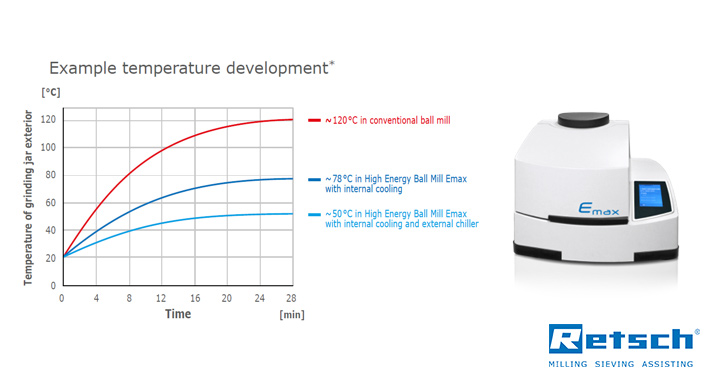

Temperature control is a major concern in fine grinding applications and that’s where the Emax comes in. Automatic water cooling removes heat from the grinding jar, reducing the wait between grinding times and the peak in temperature which occurs during standard ball milling.

New technologies pose new challenges to science and research which is also reflected in the performance features of the laboratory equipment involved. Nanotechnology, a typical example as one of the most innovative developments of our times, deals with particles in a size range from 1 to 100 nanometers that have special properties attributable to their size. Another example is materials science which uses processes like mechanical alloying to develop new materials.

Both size reduction on a nanometer scale and mechanical alloying require very high energy input. As this usually means heat build-up, effective temperature control is an essential requirement.

RETSCH is the leading manufacturer of laboratory mills for homogenization of solid samples and has developed a High Energy Ball Mill which fulfills all these requirements. With a unique maximum speed of 2000 rpm and innovative cooling options, the Emax is ideally suited for high energy applications.

- Cooled grinding thanks to internal and optional external water cooling loop.

- Reduction of temperature and pressure inside the grinding jars

- Allows continuous operation

- Temperature control mode for grinding of temperature sensitive samples, defined maximum temperature will not be exceeded

- No empirical trials for finding out required duration of grinding times and cooling breaks necessary

- Faster grinding than with any other ball mill

- Continuous grinding saves up to 75 % of total grinding time, no breaks needed in almost all applications

- Efficient grinding mechanism further reduces grinding time and results in much better grinding results

- High energy input with up to 2,000 min-1

- Better final fineness down to nanometer scale

- Mechanical alloying: Process time is reduced significantly, less caking and less formation of amorphous material

- Very narrow particle size distributions

The new High Energy Ball Mill Emax features a water cooling system and provides grind sizes in the nanometer range in a very short time. It is also suitable for mechanical alloying.