Keep an eye on your instrument, or let it do so for you!

It has been mentioned here before, all instruments need to be looked after. But when should we intervene?

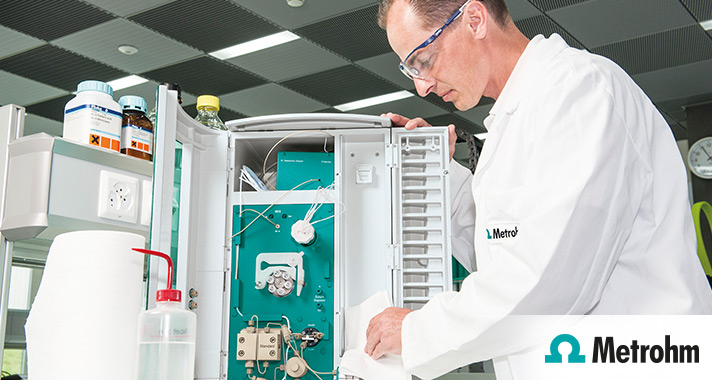

With Metrohm IC, all of the primary components are monitored by the system. Columns, pumps and detectors all monitor their running time, flow rates, temperatures and pressures with on-board chips feeding data back to the MagIC Net software.

Similarly, key consumable parts are able to be monitored in the software, requesting filter changes or guard column changes when required. Lastly, calibrations, check standards and sample results can be monitored for outliers, or shifts in chromatography.

How does the system let you know what is going on? It is up to you. The system can automatically generate on screen messages, re-calibration, in some cases, or even an email, if you choose.