A freshly prepared bath will have nearly the same content of free and total acid. During a lifecycle the amount of free acid decreases. These analyses described below allow to decide whether a bath needs to be replenished or not.

Maintaining Iron(II) and Iron(III) (Fe2+/Fe3+) ratio

Acid etching baths are used for oxide removal and cleaning of the surface of different types of steel. To keep the bath in an optimum condition the Fe2+/Fe3+ and free acid/total acid ratios must be maintained within certain limits. Auxiliary substances like hydrogen peroxide are added to influence the Fe2+/Fe3+ ratio, which is responsible for a constant activity of the bath.

The quality of the end products depends directly on the correct composition of the etching bath. Keeping these parameters in an optimum range results in a permanently higher quality and at the same time lowers costs due to lower reagent consumptions.

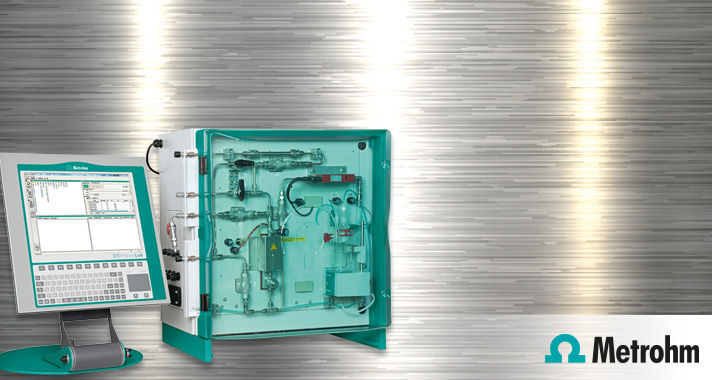

The following bulletin describes the monitoring of an etching bath in the steel industry. ProcessLab offers a solution that automatically evaluates the desired bath parameters (free acid, total acid, Fe2+ and Fe3+). Due to the flexibility offered by ProcessLab the determination of hydrogen peroxide can be integrated very easily.