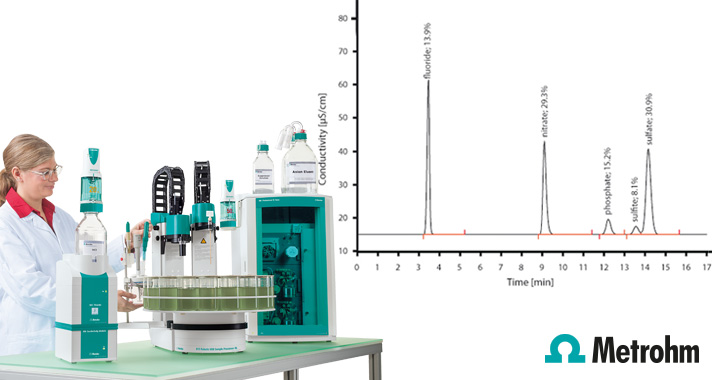

Etching solution diluted inline 1:100, column: Metrosep A Supp 5 – 150/4.0; eluent: 3.2 mmol/L Na2CO3+ 1.0 mmol/L NaHCO3, 0.7 mL/min; sample volume: 0.25 μL (internal loop)

Organic and inorganic secondary components of electroplating baths

Organic and/or inorganic additives are included in electroplating baths to control the physical properties (ductility, hardness, tear strength, brazeability, etc.) of the deposited metal layer. In the case of decorative electroplating, the visual appearance of the surface is optimised with additives. Complexing agents are also added to baths to keep large quantities of metal in solution.

Essentially, acids, bases and ions in low concentrations can be used to influence the nature of the surfaces of printed circuit boards, contacts, metal components etc. These bath additives must be analysed at regular intervals, so the production process is most efficient and a consistent end product quality ensured.

Concentrated acids in etching solutions

One of the uses of ion chromatography is to check the content of an electroplating bath. For this, the anion concentrations of the acids and acid mixtures used are determined.

Procedure:

The unique combination of Metrohm Inline Dilution Technique and a minimum injection volume (0.25 μL) makes it possible, for example, to perform fully automatic analysis of concentrated acid mixtures such as an etching solution containing 10% HF, 30% HNO3, 30% H2SO4 and 13% H3PO4.